If you’re planning a new warehouse fit-out (or trying to rescue an existing one), choosing the right pallet racking system is one of the biggest levers you have to maximise warehouse space, improve picking speed and keep everything compliant and safe.

This guide walks through the main pallet racking systems used in Australian warehouses today – where each one fits, what they’re good at, and when they’re the wrong tool for the job.

We’ll cover:

-

Selective pallet racking

-

Double-deep pallet racking

-

Drive-in pallet racking

-

Push-back pallet racking

-

Pallet live (pallet flow) systems

-

Cantilever racking

-

A quick overview of other high density storage systems (VNA, mobile, satellite, etc.)

Throughout, we’ll talk about warehouse racking, industrial storage systems, warehouse layout design and the trade-off between access, density and cost.

Before you choose a pallet racking system

Before you fall in love with any one system, it’s worth stepping back and looking at the bigger picture of your warehouse storage solutions:

Key questions to answer:

-

What are you storing?

Palletised cartons? Bulk product? Long loads (timber, steel, pipe)? Mixed SKUs? -

How many SKUs vs pallets per SKU?

High-SKU/low-pallet environments usually need higher selectivity (e.g. selective or VNA). -

How fast does stock move?

Fast-moving lines can justify high density storage systems like push-back, pallet live or satellite. -

FIFO vs LIFO?

Some products (food, pharma, anything date-critical) really need FIFO. Many others are fine with LIFO. -

What equipment do you have (or plan to have)?

Standard counterbalance, reach trucks, VNA trucks, pallet jacks, automated shuttles? -

Building constraints:

Clear height, column grid, fire aisles, dock locations, doors, and any awkward obstructions. -

Compliance & safety:

Racking must be designed, installed and inspected in line with AS 4084 and local regulations for safe warehouse storage and compliant warehouse racking.

If you’re still at the planning stage, it’s worth going deeper on design, clearances and services before you commit to a system. That’s where a dedicated planning guide fits in:

The big trade-off: access vs storage density

Most pallet racking for warehouses sits on a spectrum:

-

High access, lower density – fast, flexible, easy to change (e.g. selective pallet racking)

-

Lower access, high density – more pallets in the same footprint, but with limits on selectivity and rotation (drive-in, push-back, satellite, etc.)

A good warehouse storage system usually mixes multiple types:

-

Selective around docks and fast-pick areas

-

High-density blocks for reserve storage

-

Specialised industrial racking (cantilever, coil, cable drum etc.) for awkward stock

At a glance: which racking system fits where?

| System | Access & Selectivity | Storage Density | FIFO / LIFO | Typical Use Cases |

|---|---|---|---|---|

| Selective | Excellent – 100% pallet access | Lowest | FIFO/LIFO | General warehousing, 3PL, eCommerce, mixed SKUs |

| Double-deep | Good – pairs of pallets per location | Medium–high | LIFO (per pair) | Manufacturing, bulk SKUs, cold storage reserve |

| Drive-in | Low – by lane/row | Very high | LIFO | Bulk storage, low SKU count, seasonal or batch product |

| Push-back | Good – per lane, limited depth | High | LIFO | High-volume lines, fast movers, staging near docks |

| Pallet live (flow) | Good at pick face, lane-based | High | FIFO | Date-sensitive, high-throughput, production & dispatch buffers |

| Cantilever | Item-level access (long loads) | N/A for pallets | N/A | Timber, steel, pipe, sheet goods, bulky items |

Now let’s look at each pallet racking system in more detail.

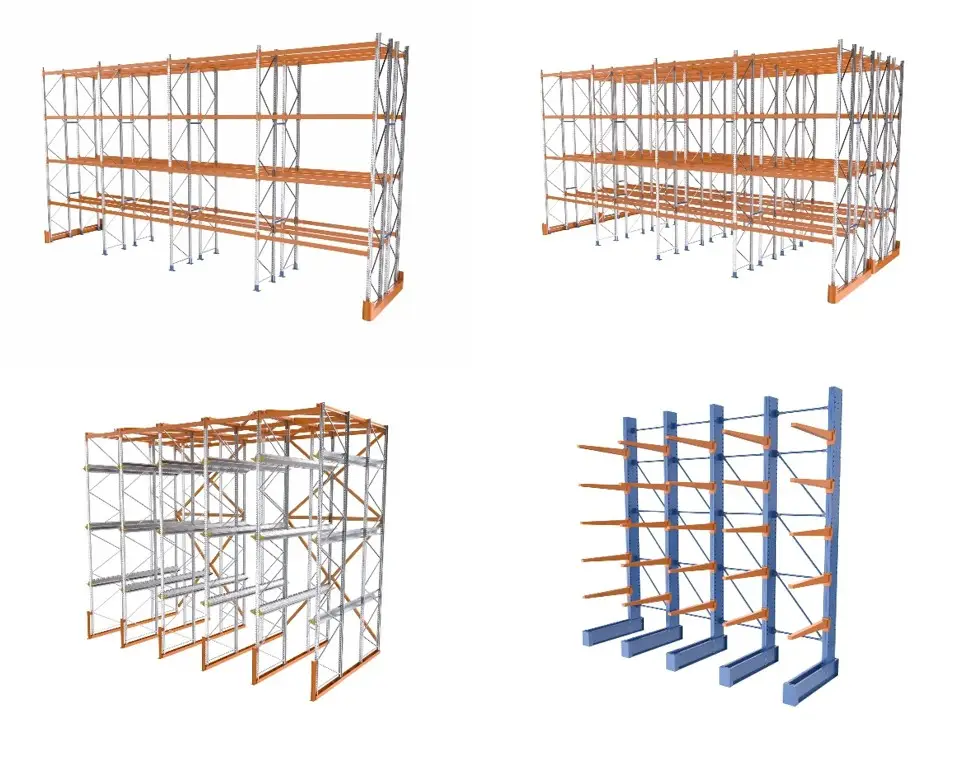

1. Selective Pallet Racking

Selective pallet racking (often called adjustable pallet racking) is the standard option in most warehouses – and for good reason. It gives you:

-

100% access to every pallet location

-

Works with most forklift types

-

Lower upfront capital cost than more specialised systems

Best for:

-

High SKU count with varying pallet quantities

-

Commercial pallet racking fitouts where flexibility is important

-

General warehouse pallet racking in 3PL, eCommerce and light manufacturing

-

Warehouses that will change or grow over time

Pros:

-

Simple to design and expand

-

Easy to re-slot, add levels, or relocate

-

Works as a base for accessories (mesh decks, pallet supports, safety barriers, etc.)

Better Storage Systems – pamphl…

Cons:

-

Lowest storage density – more aisles, fewer pallets per square metre

-

If your building cost is high (especially in cold storage), you may want a denser system

Use selective as the “default”, then add higher-density solutions where justified.

2. Double-Deep Pallet Racking

Double-deep pallet racking stores pallets two deep from the aisle. You typically need a reach truck with a double-deep attachment to access the back pallet.

Best for:

-

Medium SKU environments with multiple pallets per SKU

-

Cold stores where space is expensive, but some selectivity is still required

-

Reserve storage feeding selective or VNA pick faces

Pros:

-

Higher density than standard selective (fewer aisles)

-

Still relatively simple compared to drive-in and shuttle systems

-

A good step up in warehouse space optimisation without going fully deep-lane

Cons:

-

LIFO within each pair – the rear pallet must be loaded first, unloaded last

-

Reduced selectivity compared to pure selective

-

Needs suitable equipment and well-trained operators for safe warehouse storage

3. Drive-In Pallet Racking

Drive-in pallet racking creates deep lanes of pallets stored on support rails, with forklifts driving into the structure to place and retrieve pallets.

Best for:

-

Very high density storage systems

-

Low SKU count with many pallets per SKU (e.g. production batches, seasonal stock)

-

Freezer and coolroom environments where every cubic metre counts

Pros:

-

Very high pallet count per square metre

-

Fewer aisles and a tighter warehouse layout design

-

Ideal for “block storage” applications

Cons:

-

LIFO by lane – poor stock rotation

-

Low selectivity; changing SKUs in lanes is slow and disruptive

-

Higher risk of forklift/racking impact – needs careful design, protectors and good driver discipline

Drive-in is powerful, but it’s rarely the only system in a warehouse. It’s best used as a targeted industrial storage solution for specific product families.

4. Push-Back Racking

Push-back racking is a high-density, last-in/first-out (LIFO) system. Pallets sit on carts or roller beds in a slightly inclined lane. When you load a new pallet, you “push back” the ones already in the lane; when you remove a pallet, the next one rolls forward.

Best for:

-

Fast-moving SKUs with multiple pallets per item

-

Areas where you want a constantly full pick face

-

Staging near docks or production lines

Pros:

-

High storage density with good productivity – one aisle serves multiple deep locations

-

Pick face stays “full”, ideal for high-volume picking

-

Better selectivity than drive-in (each lane typically dedicated to one SKU)

Cons:

-

LIFO – not suitable for strict FIFO or use-by-date driven products

-

More moving components than static pallet racking systems – requires quality design and ongoing inspection

-

Higher capital cost than selective or double-deep

5. Pallet Live (Pallet Flow) Racking

Pallet live (or pallet flow) racking uses gravity roller lanes with a controlled slope. You load from the “infeed” side and pallets roll to the “picking” side – giving true FIFO (first-in/first-out) rotation.

Best for:

-

Date-sensitive products (food, beverage, pharma)

-

High-throughput environments where pallets move quickly

-

Production staging, dispatch buffers, and cross-docking zones

Pros:

-

True FIFO stock rotation

-

High density and excellent throughput

-

Reduced forklift travel – only interact at load and unload faces

-

Particularly powerful in cold storage where warehouse space optimisation is critical

Cons:

-

Higher upfront cost than selective or drive-in

-

Requires good pallet quality and consistent load weights

-

Needs careful design and testing to ensure controlled pallet speed and safe operation

6. Cantilever Racking

Cantilever racking is a specialised industrial racking system for long, bulky or awkward loads rather than standard pallets. Beams (arms) extend from vertical columns, with no front uprights, making it ideal for:

-

Timber packs

-

Steel bar, tube, pipe and RHS

-

Sheet products (timber sheet, plasterboard, steel sheet)

-

Furniture, bulky items and off-standard loads

Best for:

-

Trade suppliers (timber, steel, building products)

-

Fabrication and manufacturing plants

-

Any warehouse handling long or odd-sized goods

Pros:

-

Clear front access – no upright interference

-

Can be configured single- or double-sided

-

Adjustable arm heights for flexible storage

Cons:

-

Not designed as a primary pallet racking system (though you can store some pallets on decked levels)

-

Needs careful engineering to manage deflection and load capacity

-

Often requires bespoke industrial storage systems design

Other high-density & specialised systems (in brief)

Beyond the core systems above, there are several other warehouse storage systems that often make sense in larger or more complex facilities:

-

Very Narrow Aisle (VNA) Racking – Selective racking with very narrow aisles serviced by specialised VNA trucks. High density + full selectivity, ideal when land/building costs are high.

-

Mobile pallet racking – Racking on powered bases that open/close aisles. Excellent for cold storage – very high density while keeping access to most pallets.

-

Satellite / shuttle racking – Deep-lane racking with a powered shuttle (orbiter) carrying pallets into the lane. High-density, semi-automated solution for bulk SKUs and cold storage.

-

Raised storage areas & mezzanines – Use vertical height for small parts, carton storage or light-duty shelving above your heavy duty pallet racking.

These systems sit alongside your core warehouse racking to build a complete, efficient warehouse storage solution.

Designing the right mix for your warehouse

Most real-world warehouses don’t run a single storage system. A better approach is to match storage systems to workload:

-

Receiving & despatch zones

-

Selective or double-deep for staging and fast movers

-

Push-back or pallet live for high-volume staging lanes

-

-

Reserve storage / bulk stock

-

Drive-in, shuttle, or dense push-back block

-

VNA where high selectivity and density must coexist

-

-

Special products

-

Cantilever for long items

-

Coil, cable drum, tyre and A-frame racking for specific shapes

-

When we design industrial storage solutions, we look at:

-

SKU analysis: velocity, volume, cube

-

Material handling equipment and labour model

-

Future growth and expansion plans

-

Compliance with AS 4084

Where to next?

If you’re just starting to plan your warehouse pallet racking project, these are good next steps:

-

Clarify your requirements

-

SKUs and pallet counts

-

Required throughput (pallets in/out per hour)

-

Space available and any building constraints

-

-

Work through the planning details

-

Aisle widths, clearances, beam pitches

-

Fire egress, sprinklers, building services

-

Floor condition and loading

-

-

Get a compliant design & quote

A professional design team will help you balance warehouse space optimisation, budget, safety and future flexibility – and make sure your pallet racking systems are certified and installed correctly.

Need help choosing the right pallet racking system?

Better Storage Systems designs, supplies, installs and maintains industrial pallet racking and warehouse storage systems across Australia – from simple selective layouts through to complex high density storage systems in cold storage and high-throughput DCs.

If you’d like help matching the right racking mix to your operation, our team can:

-

Review your current storage system and layout

-

Model different racking options and capacities

-

Provide a safe, compliant warehouse racking design

-

Deliver and install turnkey warehouse storage solutions

Ready to maximise your warehouse space?

Get in touch for a free design consultation and quote.