Why pallet quality matters just as much as your racking

Most warehouse teams spend a lot of time thinking about racking design, lift equipment and layout. Far fewer spend the same effort on pallet quality – especially the condition of pallet bearers.

That’s a problem.

Your pallet racking has been engineered around a specific pallet type, size and orientation. Industry manuals make it clear that racks are designed for a defined pallet style, and that mixing pallet types or changing their orientation can make the system unsafe.

Australian Standard AS 4084 for steel storage racking assumes that pallets are compatible and in good condition when they’re placed in the rack. It covers the design, operation and maintenance of racking systems, and emphasises that the whole system – including unit loads – must work as designed to remain safe.

If your pallets are cracked, modified or missing bearers, that assumption is no longer true. The rack may still “look” fine from the aisle, but the safety margin has quietly disappeared.

This is where broken bearers create hidden rack risks.

What is a pallet bearer – and why is it so critical?

On a typical timber pallet (including common CHEP-style pallets), the bearer is the “stringer” that runs front-to-back underneath the deck boards. The bearers:

-

Transfer the load from the pallet into the beams

-

Keep the pallet rigid as it spans between beams

-

Control how load is distributed between front and rear beams

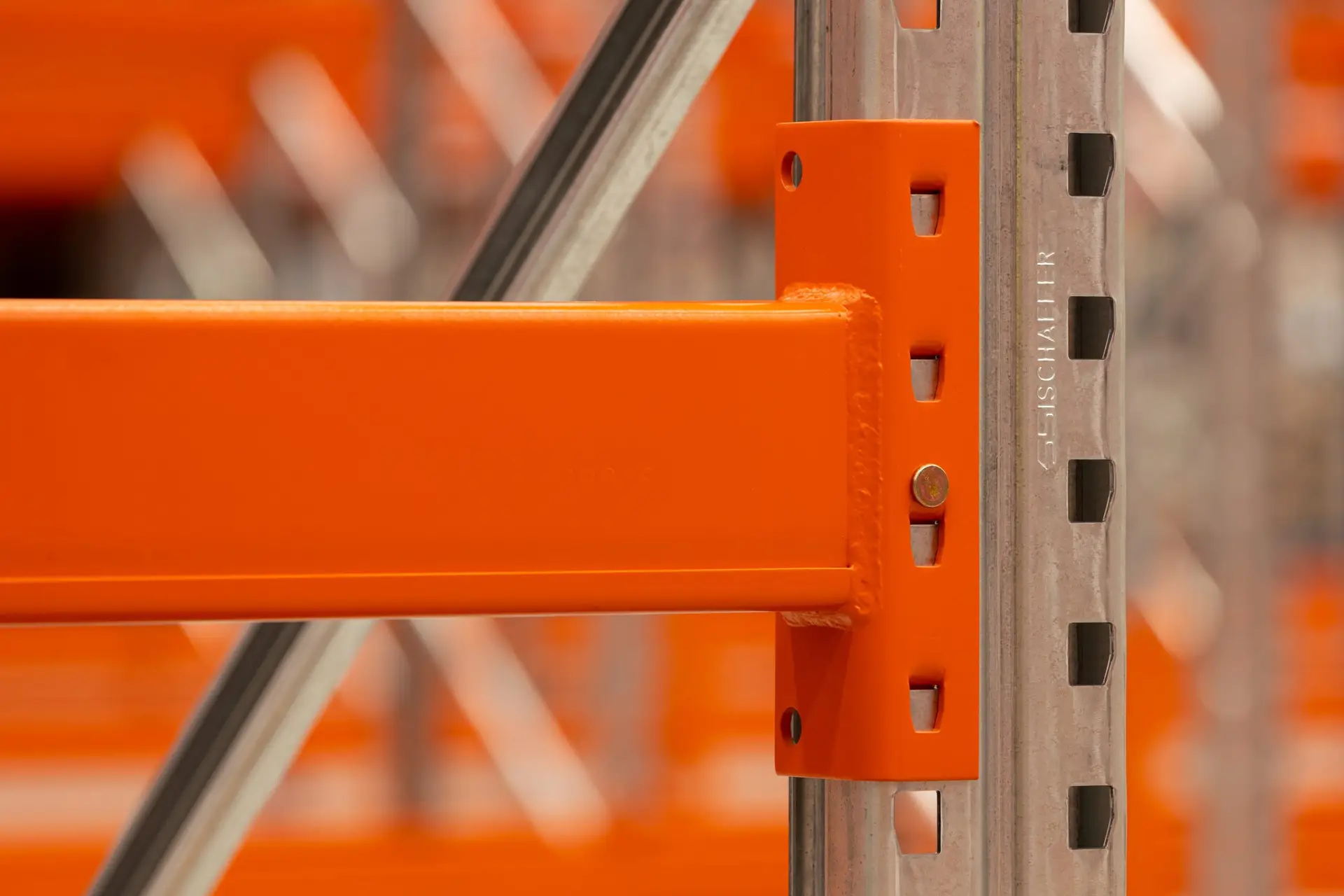

In selective pallet racking, the pallet should be placed so that the bearers span across both beams. Operating manuals stress that timber pallets must be positioned with bearers bridging the gap, and composite pallets supported directly under their blocks to avoid breaking the bottom boards.

If a bearer is broken, heavily cracked, notched or cut away, that load path is compromised. Instead of spreading the load evenly across both beams, you can end up with:

-

Point loads on one beam or one corner

-

Extra bending in the deck boards

-

Twisting and prying forces on beam connectors

-

Higher stress on upright frames than they were designed for

From the floor, the pallet might look “good enough”. Underneath, it can be one impact or overload away from failure.

How broken bearers damage your pallet racking

1. Concentrated point loads on beams

Beams are designed for an evenly distributed unit load – for example, two 1,000 kg pallets per beam level, positioned correctly so bearers sit squarely across both beams.

If a bearer is broken or missing:

-

The pallet may sag in the middle, loading just one beam

-

A block or remaining bearer can “knife” into a beam top flange

-

Over time, you see local bending, flange distortion or cracking

Operators may only notice that pallets get harder to place or retrieve at that location. The underlying cause – damaged pallets – can be missed until a beam is visibly deformed or fails.

2. Twisting frames and loosening connections

Uneven pallet support changes how forces travel through the rack. When one beam is taking more than its share of the load, that imbalance can:

-

Pull frames out of plumb

-

Stress bracing and baseplates

-

Loosen beam connectors and safety locks

AS 4084 and major manufacturer manuals emphasise that even moderate damage or misalignment can significantly reduce the load-carrying capacity of racking and erode the original safety factors.

Again, the rack may still be standing, but it’s no longer performing as designed.

3. Increased risk of pallet collapse and falling product

A pallet that can’t safely span between the beams becomes a direct falling-load hazard. Guidance documents are clear: pallets must be in good condition, free from loose or broken boards and protrusions, and capable of supporting themselves (and the load) when spanning between supports.

A broken bearer increases the likelihood that:

-

The pallet fails as it’s put away or retrieved

-

Deck boards break suddenly under live load

-

Product falls to lower levels or into aisles

Near-misses here are often written off as “bad pallets” or “forklift error”, when the root cause is a lack of pallet quality controls.

4. Compliance, liability and insurance implications

AS 4084 places responsibility on the user to operate and maintain racking in accordance with the design and the standard. If damaged or non-compliant pallets are routinely used, it becomes harder to demonstrate that the system is being operated as intended.

-

The condition and type of pallets in use

-

Whether pallet quality was part of your inspection regime

-

Whether damaged pallets were quarantined and removed from service

If pallet quality is not documented, it’s difficult to argue that risks were being actively managed.

The hidden nature of bearer damage

One of the biggest challenges with bearer damage is that it’s easy to miss. From a ground-level glance:

-

The top deck looks intact

-

The load appears stable

-

The pallet footprint lines up with the beams

But underneath, you may find:

-

Split or crushed bearers at fork entry points

-

Notches or “DIY” cut-outs to suit machinery or conveyors

-

Rotten, soft or oil-soaked timber

-

Missing blocks or repairs with non-standard timber

Operating manuals recommend checking beneath the pallet for loose, split or damaged boards before loading, and explicitly state that damaged pallets must not be entered into the system and should be removed as they occur.

If this isn’t happening every day at the forklift, damaged pallets will eventually reach higher levels, where they’re harder to see and much harder to recover safely.

Practical signs your pallet bearers are putting your rack at risk

During daily operations, watch for:

-

Pallets that rock or bounce when placed on beams

-

Visible sagging across the beam span, especially with heavier loads

-

Repeated beam damage in the same bay or level

-

Forks “punching through” deck boards when lifting from the floor

-

Operators complaining that a particular level is hard to load

On the pallets themselves, train your team to spot:

-

Cracked, split or crushed bearers

-

Notched or cut-away bearers that no longer sit properly on beams

-

Missing or loose blocks in block pallets

-

Heavy staining, rot or water damage in timber

-

Protruding nails, plates or repairs that can catch on beams or other pallets

Any of these are clear reasons to quarantine the pallet and, where applicable, involve your pallet supplier.

Building a pallet quality standard for your warehouse

To control this risk, pallet quality needs to be treated like any other engineered element of your storage system. A simple “pallet quality standard” typically includes:

1. Defined acceptable pallet types

-

Specify approved pallet sizes and styles for each racking area

-

Document required orientation (which face is handled and stored)

-

Avoid mixing incompatible pallet designs in the same rack unless it has been explicitly assessed

This aligns with the way racking systems are designed around specific pallet characteristics.

2. Clear reject criteria for pallets

Create a visual guide that shows what is not acceptable, for example:

-

Any cracked, broken or missing bearer

-

Crushed or missing blocks

-

Severe deck-board damage or missing boards in load-bearing locations

-

Excessive rot, moisture damage or contamination

Keep this guide at dispatch and receiving, and build it into your onboarding and refresher training.

3. A simple pallet quarantine process

Make it easy for forklift operators and pickers to do the right thing:

-

Designate a pallet quarantine area

-

Require damaged pallets to be moved there immediately

-

Nominate responsibility (e.g. supervisor or maintenance) for assessment and disposal

This mirrors the approach recommended in racking operating manuals, where damage is reported and dealt with under a defined procedure rather than left in service.

4. Integrate pallets into your inspection schedule

Most racking guidance recommends daily operator checks and periodic inspections by a technically competent person.

Extend those inspections to include pallets:

-

Check sample pallets at each inspection cycle

-

Pay special attention to high-turnover areas and heavy unit loads

-

Record recurring pallet issues (e.g. certain suppliers, product lines or load types)

Training your team: from “just pallets” to critical equipment

Pallets are often seen as consumables. To change that mindset:

-

Include pallet condition and bearer positioning in forklift driver training, alongside safe loading/unloading procedures and alignment in the rack.

-

Reinforce that operators must never “nudge” or drag pallets in the rack to straighten them, as this adds extra loads into beams and frames.

-

Empower staff to tag and remove suspect pallets without fear of slowing the shift.

The goal is simple: no damaged pallets in the racking, ever.

How Better Storage Systems can help

Better Storage Systems doesn’t just supply pallet racking – we support the full lifecycle of your storage system: design, installation, certification, ongoing racking safety audits and repairs, and make-good projects.

When it comes to pallet quality and bearer damage, our team can help you:

-

Review whether your current pallets are compatible with your racking design

-

Identify high-risk areas where damaged pallets are likely to appear

-

Recommend accessories such as pallet support bars, mesh decks or rack protection where appropriate

-

Integrate pallet condition checks into your pallet racking safety audits

-

Plan repairs or reconfiguration works in line with AS 4084 and manufacturer guidance

If your racking is already showing signs of beam or frame damage, combining a comprehensive racking inspection with a review of pallet quality is often the fastest way to close the loop and restore your safety margin.

Key takeaways for CEOs, warehouse managers and operators

-

Pallet quality matters as much as rack design – your racking is engineered around a specific pallet type, condition and orientation.

-

Broken bearers create hidden risks, including point loads, twisted frames and falling product.

-

Damaged pallets must never enter the rack – they should be quarantined and removed from service, not “used up” at higher levels.

-

A clear pallet quality standard, backed by training and inspections, turns pallet checks into a normal part of safe operation.

-

Partnering with a specialist for pallet racking audits, repairs and upgrades helps ensure your system, pallets and processes all align with AS 4084 and manufacturer guidelines.