Why upright pitch and beam hook spacing matter

If you’re buying extra beams, mixing brands, or reconfiguring existing pallet racking, two small dimensions can make or break the job:

-

Upright pitch – the vertical spacing of the holes or slots in the upright frame.

-

Beam hook spacing – the vertical spacing between the beam connector hooks that sit into those holes.

If these don’t match, beams won’t seat properly in the uprights. That can lead to:

-

Misaligned or partially engaged connectors

-

Load signs and engineering calculations no longer matching the actual system

-

Non-compliance with standards such as AS 4084 and the manufacturer’s tested configuration

The good news: with a tape measure, a simple method, and a few minutes per bay, your team can capture these measurements accurately and hand clean data to your racking supplier or engineer.

This guide zooms right in on the steel – how to measure upright pitch and beam hook spacing step-by-step – so you can order compatible components and keep your pallet racking safe and compliant.

Key terms in plain English

Before you start measuring, it helps to lock in a few definitions used in racking manuals and standards:

-

Upright – the vertical frame (or “post”) with punched holes or keyholes where beams connect.

-

Beam – the horizontal member that carries the pallets. Two beams facing each other form one beam level.

-

Upright pitch – the distance between the centres of two consecutive holes/slots on the upright. Most modern pallet racking adjusts in regular increments (commonly around 50, 50.8, 75 or 76.2 mm, depending on the system).

-

Beam pitch (vertical beam spacing) – the distance from one beam level to the next, measured from the top of one beam to the top of the next. This is the dimension used in capacity tables.

-

Beam hook / connector – the formed plate at each end of the beam, with hooks that lock into the upright holes (usually with a safety clip).

-

Beam hook spacing – the vertical distance between the centres of the top and bottom hooks on the connector plate. This must match the upright pitch (or a multiple of it) for a proper fit.

Think of upright pitch and hook spacing as the “toothing” of your system. If the teeth don’t match, you can’t safely mesh components, even if they almost look right.

Before you start: safety and tools

1. Make it safe

-

Only measure in clear bays – no pallets on the beams you’re working on.

-

Isolate the aisle where practical and follow your normal lock-out or exclusion procedures.

-

Never climb racking; use platforms or access equipment that meets your site rules.

2. Tools you’ll need

-

A metric tape measure in good condition (with a solid hook).

-

A permanent marker or paint pen.

-

Notepad or measurement worksheet (or your warehouse measurement template from Better Storage Systems).

-

Optional:

-

Small steel ruler for tighter checks.

-

Phone camera to capture each upright and beam label alongside the measurements.

-

Step-by-step: how to measure upright pitch

Step 1 – Choose a good upright

Pick an upright that:

-

Is straight, undamaged and easy to access.

-

Has clearly visible holes or keyholes.

-

Represents the majority of that run (same brand and profile).

If your warehouse has multiple brands or generations of racking, you’ll repeat this process for each type.

Step 2 – Identify the hole centres

To measure upright pitch correctly, you’re measuring centre-to-centre between two adjacent holes – not the gap between them.

On most selective pallet racking uprights you’ll see one of two patterns:

-

Keyhole style – “figure 8” or teardrop openings.

-

Round/slot style – round or slotted holes in a vertical line.

Pick two holes directly above one another in the same column. Mark the centre of each hole lightly with your marker if that makes it easier to read.

Step 3 – Measure over multiple pitches

For better accuracy, don’t just measure between two holes. Instead:

-

Hook the tape into the centre of a hole near eye level (or measure to an easily repeatable reference point on the hole shape).

-

Count four or five holes up (so you’re spanning four or five pitches).

-

Measure to the centre of that higher hole and note the total distance.

Example:

-

You measure from the centre of the first keyhole to the centre of the fifth keyhole above it.

-

The total distance reads 305 mm.

You’ve spanned four pitches, so:

305 mm ÷ 4 ≈ 76.25 mm

That tells you the system is almost certainly a 76.2 mm pitch upright, which is a very common pattern in Australian-market pallet racking.

Repeat the measurement once or twice in different parts of the upright to confirm the result.

Step 4 – Record the pitch and upright details

In your notes or worksheet, record:

-

Measured pitch (e.g. ~76.2 mm, ~75 mm, ~50 mm).

-

Upright profile (e.g. nominal front face width and depth if you know it).

-

Any visible stamps or markings on the upright.

-

The location (aisle, bay, frame number).

This information is what your racking supplier or engineer will use to identify the brand family and confirm whether new components are compatible.

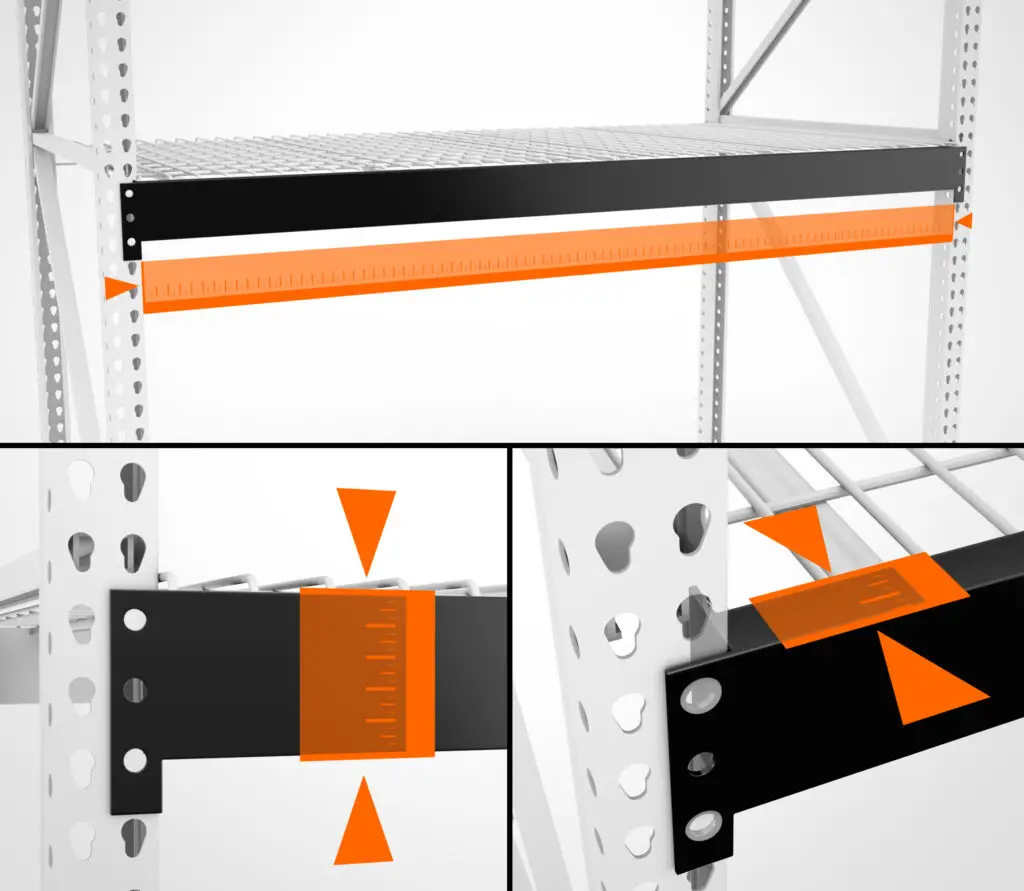

Step-by-step: how to measure beam hook spacing

Once you know the upright pitch, you need to confirm that your beams are built for the same pattern.

Step 1 – Make sure the beam is unloaded

Never remove or loosen a loaded beam. Clear the pallets first, then:

-

Either measure the connector while the beam is still in place, or

-

For a more precise measurement, remove one beam (following your safe work method and using appropriate access equipment).

Step 2 – Measure vertical hook spacing

On one beam end:

-

Find the top hook and mark a point you can consistently measure from (for example, the centre of the hook or the top edge where it bears in the slot).

-

Find the bottom hook in the same vertical line and mark the equivalent point.

-

Measure the vertical distance between those two points.

Again, for accuracy, some connector plates have three or four hooks. You can:

-

Measure from the first to the third hook and divide by two; or

-

From first to fourth and divide by three.

Your result should closely match the upright pitch or a simple multiple of it. For example:

-

Upright pitch ≈ 76.2 mm

-

Measured hook spacing ≈ 152–153 mm (two pitches) or ≈ 228–229 mm (three pitches)

That indicates the beam is designed for that pitch family.

Step 3 – Check horizontal bearing and connector style

While you’re there, also capture:

-

Horizontal spacing between the hooks (front to back) if there are staggered hooks.

-

The overall height of the connector plate.

-

The beam section (box beam, open beam, RHS or step beam) and its face height (e.g. 93 mm box beam).

Take a quick photo of the connector and beam profile – these visual details help your racking specialist match new components more confidently.

Step 4 – Compare with the upright pitch

Now compare your numbers:

-

If the beam hook spacing is an exact match or a neat multiple of the upright pitch, that’s a good sign.

-

If it’s clearly out – for example, a beam hook spacing that suits a 75 mm pitch frame being offered for a 76.2 mm pitch upright – do not attempt to “make it fit” by forcing, shimming, drilling or grinding. That will void engineering assumptions, may breach AS 4084, and can seriously weaken the connection.

Reading your results: what the numbers tell you

Once you’ve measured several locations across your warehouse, patterns start to emerge.

1. Consistent pitch = one main system

If almost everything measures at the same pitch (for example, ~76.2 mm) and the beam hook spacings are consistent multiples of that, you probably have one dominant selective pallet racking system with standardised uprights and beams.

#2-Design Details – Selective P…

In this case, adding compatible new beams or frames is usually straightforward – provided you stay within the original manufacturer’s design scope and AS 4084.

2. Multiple pitch families = mixed brands or generations

If you see two or more distinct pitches in the same shed – say, some frames measuring around 75 mm, others 76.2 mm, others near 50 mm – you’re likely dealing with:

-

A mix of brands

-

Older systems alongside newer installations

-

Used racking that’s been brought in over time

Here, you should treat each pitch family as a separate system. Beams and frames should not be mixed across systems unless a competent engineer designs and certifies the configuration as a whole.

3. Why beam spacing feeds into capacity

Standards and manufacturer manuals link upright capacity directly to the maximum vertical beam spacing – the distance between beam levels – as well as the upright profile and thickness. Larger spacing generally reduces the frame’s allowable load.

That means:

-

If you move beam levels or add extra levels without engineering checks, you may invalidate the original design.

-

Upright pitch and hook spacing allow you to adjust levels in controlled increments that align with tested capacity tables, rather than ad-hoc drilling or cutting.

Common mistakes when measuring racking

Even experienced teams can get caught by small measurement errors. Watch for these traps:

-

Measuring the wrong thing

-

Calling the distance between beam levels “upright pitch” – they’re related but not the same.

-

-

Measuring edge-to-edge, not centre-to-centre

-

Always work from hole/slot centres or equivalent reference points, especially on keyhole uprights.

-

-

Only taking one measurement

-

Measure over several pitches and in more than one spot; small tape errors add up.

-

-

Measuring damaged steel

-

Bent uprights, stretched keyholes or hammered connectors give misleading numbers – note the damage and measure a sound location nearby.

-

-

Mixing mm and inches

-

AS 4084 and most Australian installations work in millimetres. Double-check you’re not reading the imperial scale on the tape.

-

-

Assuming near-enough is good-enough

-

A 1–2 mm difference once might be tape error; a consistent 1–2 mm difference over several measurements usually means a different pitch family. Treat it as incompatible unless confirmed otherwise.

-

When to bring in Better Storage Systems

You don’t need to become a racking engineer – but good measurements make it much easier for specialists to help. It’s time to call in Better Storage Systems if:

-

You’re planning a warehouse re-fit or extension and want to reuse or supplement existing racking.

-

You’ve discovered multiple pitch families or brands in the same shed and aren’t sure what can be mixed.

-

You’re buying used pallet racking and want to confirm it’s compatible and can be certified to AS 4084 in your configuration.

-

You’re updating pallet racking load signs and need current, engineer-backed capacities for each bay type. betterstorage.com.au

-

You’d like a full pallet racking safety audit and repair plan, including inspection of uprights, beams, connectors and tolerances.

Better Storage Systems can take your upright pitch and beam hook spacing data, confirm system identification, design compatible layouts, and provide installation, audits and repairs across Australia – so every beam and upright in your warehouse works as one engineered, compliant system.