Why “Frame Depth vs Pallet Overhang” Isn’t Just a Design Detail

On a drawing, frame depth and pallet overhang look like a couple of small numbers in the middle of a big layout.

In a live warehouse, they decide whether:

-

Pallets sit stably on beams or rock and sag

-

Forklift drivers glide loads in… or fight constant “hang-ups” on uprights

-

You stay inside AS 4084 and manufacturer clearances – or quietly step outside your certified design

This article goes deeper than basic layout. Instead of re-explaining aisle widths and beam levels, it focuses specifically on frame depth vs pallet overhang – what actually matters for safety, handling and long-term rack health.

If you’re a CEO or warehouse manager signing off on new racking, this is one of the most important dimensional decisions you’ll make.

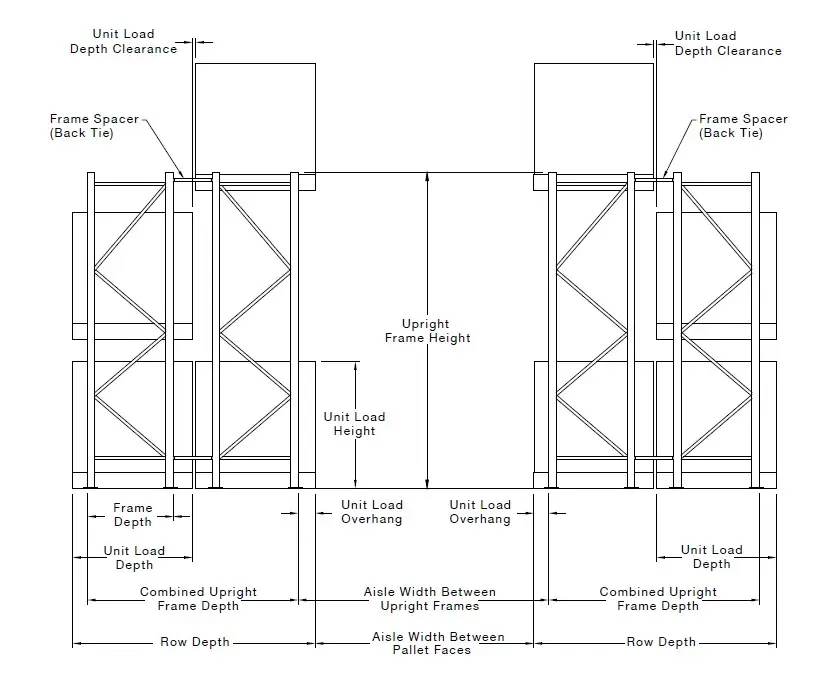

Key Concepts: Pallet Depth, Frame Depth, Overhang and Clearances

Before you can judge whether your design is safe, you need to be clear on four basic terms.

Pallet depth

The front-to-back dimension of the pallet (and load), measured perpendicular to the aisle.

-

For a standard Australian CHEP/Loscam pallet, that’s 1165 mm × 1165 mm.

Frame depth

The distance between the front and rear beams/uprights in a bay.

-

Common pallet racking catalogues show frame depth series like 610 / 838 / 1219 mm for selective racking frames.

Pallet overhang

How far the pallet projects beyond the support point. In selective racking, this usually means:

-

How much the pallet overhangs beyond the front and rear beams, and

-

How much the load itself overhangs the pallet (cartons bulging, plastic wrap “fanning”, etc.).

Depth clearance

Any spare space behind the pallet – for example, between the rear pallet and an upright in a double-deep system, or between two back-to-back pallets.

Design manuals and standards call out minimum clearances in three directions – side-to-side, vertical and depth – so operators can place and remove loads without constantly hitting steel.

What the Standards and Manuals Actually Care About

AS 4084 and manufacturer manuals don’t obsess over one “magic” frame depth. What they care about is:

-

Clearances

-

Minimum horizontal clearance to uprights

-

Minimum gap between adjacent pallets

-

Minimum vertical clearance between pallet loads and beams above

-

-

How the load is supported and transferred into the steel

-

Pallet bearers must sit properly on the beams, not hanging off the front edge

-

Overhang must be controlled so pallets don’t push each other or hit uprights

-

-

Compatibility between pallet type and rack design

-

Pallet size, quality and type (CHEP, export, one-way, post pallets, skids)

-

Rack designed and certified for that specific unit load

-

SafeWork and other regulators are explicit: swapping to larger or smaller pallets than the design allows, or running with uncontrolled overhang, can push loads off their supports or let pallets drop through. SafeWork SA+1

Typical Design Combinations in Australian Warehouses

While every job should be engineered, some patterns are common in Australian selective pallet racking:

-

CHEP/Loscam 1165 × 1165 pallets

-

Often paired with 838 mm frames, giving controlled front and rear overhang with space behind for depth clearance.

-

-

1,000 mm deep pallets (common in imports)

-

Frequently used on 900 mm frames, giving ~50 mm overhang front and rear.

-

-

Deeper frames (e.g. 1,219 mm)

-

Used for non-standard pallets, drums on cradles or bulky loads where more bearing and less overhang is needed.

-

The earlier Better Storage Systems guide on warehouse layout basics: aisle widths, clearances and beam levels steps through clearances in three dimensions. This article zooms in specifically on how frame depth vs pallet overhang affects what happens on the beams.

When Frame Depth Is Too Shallow

It’s tempting to squeeze in extra overhang because “the pallet is strong”. Here’s what happens when frame depth is undersized relative to pallet depth:

1. Pallets fight with uprights

If the frame depth is close to, or equal to, pallet depth, there’s little or no space for:

-

Slight pallet size variations

-

Load bulging over the edge of the pallet

-

Wrap tails and corner protection

Result: pallets rub on uprights every time they go in or out, leading to:

-

Upright damage

-

Pallets “hung up” and sitting crooked

-

Operators nudging or “bumping” loads into place with the truck

2. Point loading and pallet damage

With too much overhang and too little pallet on the beams:

-

Pallet bottom boards work harder and may crack over time

-

Loads become more sensitive to pallet quality and grain direction

-

The risk of a board breaking and the pallet tipping increases

Some international guidance suggests at least 50–75 mm of safe overhang at front and rear on standard racks, but always within a design that has been engineered for that exact pallet and load.

3. Clearances vanish at the back

In double-deep or back-to-back runs, undersized frame depth plus generous overhang can eliminate the required depth clearance between pallets or between pallet and upright. That can:

-

Push rear pallets into spine bracing or safety backstops

-

Increase the chance of pallets nudging each other off supports

-

Make it harder to maintain proper flue spaces for sprinklers

When Frame Depth Is Too Deep

Oversizing frame depth can feel “safe”, but it introduces other problems.

1. Pallets sit too far in

If the pallet sits a long way back from the front beam:

-

Drivers lose a clear visual reference when placing loads

-

Pallets may be parked too deep, reducing aisle clearance

-

In push-back or flow systems, over-deep frames can interfere with cart or roller geometry

2. Loads lose bearing where you expect it

If the pallet is much smaller than the frame:

-

The bearers may end up sitting in an unintended position on the beams

-

Front and rear overhang might not be symmetrical, even if the driver believes it is

-

Pallets can be parked with all the weight closer to one beam, increasing local beam and connector stresses

This is why both AS 4084 and EN 15620 push designers to work from actual pallet size and position, not just beam and frame dimensions. NormSplash

How Much Pallet Overhang Is “Right”?

There is no single “Australian overhang number”. The right amount depends on the combination of:

-

Pallet depth and construction

-

Frame depth

-

Beam size and capacity

-

Unit load weight and height

-

Forklift type and approach angle

However, design manuals and Q&A resources tend to converge on a similar ballpark:

-

A controlled overhang at front and rear so the pallet sits securely and the operator can see it on the beams

-

Enough pallet on the beams that the bearers are fully supported

-

Depth clearances maintained behind the pallet, as per the engineered design

Most importantly, AS 4084-aligned user manuals warn against overhanging loads that have not been specifically designed and certified for that configuration.

If your racking hasn’t been engineered for cartons or product hanging over the pallet edge, you can’t assume it’s safe.

Safety and Handling Risks When You Get It Wrong

From Better Storage Systems’ audits across Australia and New Zealand, the most common issues linked to poor frame depth / overhang choices include:

-

Frequent rack strikes

Pallets catching uprights on the way in or out because there’s no room for overhang and minor misalignment. -

Damaged or collapsed pallets

Bottom boards snapping when too much of the pallet sits off the beam or when the overhang is excessive for the pallet condition. -

Hidden non-compliance

Racking originally certified for one pallet size being used for larger or different pallets – but with load signs and documentation never updated. -

Poor forklift productivity

Drivers slowing down, taking extra “micro-corrections” or relying on bumping loads into place rather than placing them cleanly first time. -

Flue space and fire design issues

Uncontrolled overhang reducing designed gaps between back-to-back pallets, which can impact sprinkler performance.

None of these show up on the frame depth line of a quote – but they show up fast in damage reports and near-miss logs.

A Practical Decision Guide: Choosing Frame Depth vs Pallet Overhang

When you sit down with a design, use these steps as a sanity check.

Step 1 – Lock in your “design pallets”

List, for each zone:

-

Pallet type (CHEP, Loscam, one-way, export, plastic, post pallet)

-

Pallet depth and width (actual, not “roughly a metre”)

-

Typical overhang of the load beyond the pallet

This is the same stock-driven thinking used in Better Storage’s pallet racking 101 and buying guides – you’re designing for real loads, not generic pallets.

Step 2 – Choose a frame depth that fits your main pallet

Work with your racking supplier to:

-

Select a frame depth that gives controlled front/rear overhang for the main pallet size

-

Confirm that depth clearance behind pallets (especially in back-to-back or double-deep runs) can still be achieved

At this stage, you’re trading off:

-

Stability and support vs

-

Enough room for minor pallet variation, bulging loads and clearances

Step 3 – Check the extremes, not just the average

Ask your team:

-

What’s the tallest and heaviest pallet that will live in this zone?

-

What’s the largest pallet footprint that might be introduced “temporarily”?

-

Are any overseas or custom pallets in the mix that don’t match CHEP dimensions?

Designers should test these extremes in their calculations, not just the “typical” pallet. SafeWork SA+1

Step 4 – Confirm with load diagrams and clearances

Before you sign off:

-

Ask for a simple diagram showing pallet position on the beams, overhang front/back and all clearances

-

Verify that it aligns with AS 4084 clearances and the manufacturer’s user manual

-

Ensure the same assumptions appear on your pallet racking load signs and layout drawings

This is where the earlier blog on pallet racking load signs links tightly with frame depth vs pallet overhang – the sign must reflect the real pallets and support conditions in each bay.

Step 5 – Bake it into operating rules

Even the best design fails if operations ignore it.

-

Standardise pallet types by zone where possible

-

Make it clear where non-standard pallets can and cannot go

-

Integrate pallet size and condition checks into your pallet racking inspection checklist and toolbox talks SafeWork SA

Special Cases: Post Pallets, Stillages and Oversized Loads

Not all “pallets” are timber squares.

Post pallets and stillages

Post pallets and steel stillages put concentrated loads through small feet or runners, not along pallet bearers. If you sit them directly on beams designed for CHEP pallets, you can:

-

Overload small sections of the beam

-

Create unintended point loads that the original design never considered

These loads often need:

-

Skid channels or stillage channels to spread point loads, and

-

Specific design work on frame depth and pallet/foot positioning

Oversized cartons or product overhang

AS 4084-aligned manuals warn against loads overhanging the pallet unless the rack is specifically designed for it.

If your product routinely overhangs the pallet:

-

Simply increasing frame depth is not enough

-

You may need deeper beams, decking, backstops or end frame extensions

-

Your fire engineer may need to reassess flue spaces and sprinkler performance

Mixed pallets in the same bay

A bay designed for 1165 mm pallets with controlled overhang may not safely accept:

-

Small export pallets that can drop through

-

Larger pallets that push into uprights or rear pallets

If that’s your reality, consider:

-

Zoning different pallet types to different runs

-

Using decking or pallet supports in “mixed” zones

-

Having those zones explicitly covered in your engineered design and load documentation

A Simple Checklist for CEOs and Warehouse Managers

You don’t need to do the math – but you do need to ask the right questions. On your next walk-through or project meeting, use this checklist:

-

Do we know our design pallets by zone?

-

Sizes, weights, heights and pallet types documented?

-

-

Is the frame depth on drawings clearly matched to those pallets?

-

Or was it just “whatever was standard in the catalogue”?

-

-

Can someone show you, in writing, the designed overhang and clearances?

-

Front, rear and depth clearance for each run?

-

-

Do the load signs and layout drawings match how we actually use the racks?

-

Same pallets, same beam levels, same capacities?

-

-

Are non-standard pallets controlled?

-

Clear rules on where post pallets, oversize pallets and export pallets can be stored?

-

If the answer to any of these is “I’m not sure”, it’s a good time to get your system rechecked.

How Better Storage Systems Can Help

Better Storage Systems designs, installs and maintains AS 4084–compliant pallet racking systems across Brisbane, Sydney and throughout Australia – with frame depth, pallet overhang and clearances engineered as part of a complete solution, not left to chance.

Depending on where you are in the journey, the team can:

-

Design new pallet racking installations around your actual pallet types, fork trucks and building envelope

-

Provide a comprehensive design and quote service with layout drawings, load calculations and beam/frame schedules

-

Conduct a formal racking safety audit and repair to AS 4084, including checking pallet compatibility, clearances, frame depth and overhang in the field

-

Help update your load signs and documentation so what’s on the board matches what’s in the racks

If you’re planning a new fit-out or suspect your current system has “grown” away from its original design, getting frame depth vs pallet overhang right is one of the fastest ways to improve safety, handling and long-term rack performance.