Choosing pallet racking is a business decision, not just an equipment purchase.

The right pallet racking system will help you maximise warehouse space, speed up picking, reduce damage and support safe, compliant operations. The wrong choice locks you into poor warehouse layout design, high running costs and constant workarounds.

Step 1 – Get clear on what you’re actually trying to fix

Before you look at frames and beams, be clear on the problem you’re solving. Common goals:

-

Increase storage capacity without moving sheds

-

Improve workflow – fewer touches, fewer bottlenecks at docks or production

-

Reduce damage to product and racking

-

Create safe warehouse storage and tick the compliance box

-

Make room for future growth or new product lines

Write down what “success” looks like in 12–24 months. For example:

-

“Increase pallet capacity by 30% without adding staff”

-

“Create a compliant, auditable warehouse storage system for AS 4084 inspections”

This becomes your yardstick when you compare racking options.

Step 2 – Analyse your stock, not just your space

The best warehouse racking is driven by inventory, not by the shed.

Key things to nail down:

-

SKU profile

-

How many SKUs do you carry?

-

How many pallets per SKU (average and peak)?

-

High-SKU/low-pallet environments usually need higher selectivity; low-SKU/high-pallet environments can justify high density storage systems.

-

-

Velocity

-

Fast-moving vs slow-moving lines

-

Seasonal peaks (e.g. EOFY, Christmas, harvest, project work)

-

-

Load details

-

Pallet type (CHEP/Loscam/one-way/custom) and condition

-

Pallet dimensions and clear loaded height

-

Average and maximum pallet weight

(These directly drive beam type, frame capacity and safe working load signage. )

-

-

Rotation & rules

-

FIFO required for shelf-life?

-

Or is LIFO acceptable for steel, timber, bulk raw materials?

-

Once you have this, you can start to see which pallet racking for warehouses will actually fit your stock and movement patterns.

Step 3 – Map your building and constraints properly

You can’t choose industrial racking in isolation from the building.

At minimum, capture:

-

Clear height to underside of lowest obstruction

-

Column grid and any internal walls

-

Dock locations, roller doors, staging areas

-

Sprinklers, services, low beams, pits, drains and speed humps

-

Slab condition and known slab loading issues

Then think about your warehouse layout design:

-

One-way vs two-way forklift traffic

-

Separate pedestrian walkways and crossings

-

Fire aisles and egress

-

Where inbound and outbound staging will sit

Helpful supporting resources on the site map include:

-

Warehouse Layout Basics: Aisle Widths, Clearances, and Beam Pitch

-

How to Measure Your Warehouse for Pallet Racking (No CAD Needed)

-

Warehouse Measurement Worksheet (download)

Getting the measurements right up front makes it much easier to choose between pallet racking systems later.

Step 4 – Decide your storage strategy (before picking a system)

Now you can think about storage strategy rather than individual products.

Key trade-offs:

-

Selectivity vs density

-

Do you need 100% access to every pallet at all times?

-

Or are you comfortable with lane-based access for some product families?

This is where you decide your blend of warehouse pallet racking:

-

Highly selective zones (e.g. adjustable pallet racking/VNA)

-

High-density zones (e.g. drive-in, push-back, pallet live, shuttle)

-

Specialised zones (cantilever, longspan, duty warehouse shelving)

-

-

Pick-face vs reserve storage

-

Do you need full pallets at the pick face, or will you break down into cartons?

-

Do you need industrial storage systems like carton live / small parts shelving above or alongside your pallet racking?

-

-

Automation readiness

-

Are you likely to add WMS-based location control, RF, pick-to-voice or shuttles later?

-

If yes, design your storage system with consistent bay sizing, clear labelling and good P&D locations from day one.

-

If you want help comparing the major systems in detail, that’s where a dedicated comparison guide fits:

Step 5 – Match racking to your equipment and labour model

Your warehouse storage solutions must work with the people and machines you already have (or plan to invest in).

Consider:

-

Forklift fleet

-

Counterbalance, reach, VNA, walkie stackers, order pickers

-

Mast heights vs proposed rack heights

-

Aisle width requirements for each truck type

-

-

Labour and shift pattern

-

How many operators per shift?

-

Do you rely on casuals/temps (which changes how forgiving your layout needs to be)?

-

-

Travel and congestion

-

Are you constantly blocked in front of docks or at cross-aisles?

-

Would a different orientation of warehouse racking reduce travel time?

-

There’s a planned beginner guide specifically for this interaction between forklifts and racking:

Step 6 – Look at total cost of ownership, not just the quote

Two quotes for “the same” industrial pallet racking can look similar on price, but very different over 10–15 years.

Look beyond the upfront supply-and-install number:

-

New vs used

-

Used racking can look cheaper, but can create headaches with certification, missing components and mismatched brands.

-

There’s a dedicated guide on Used vs New Racking in Australia: Cost, Compliance & Safety.

-

-

Expandability

-

Can you easily add bays, levels or blocks as you grow?

-

Is the system a standard local brand with good parts availability?

-

-

Downtime & disruption

-

What does a reconfiguration or repair programme cost you in lost throughput?

-

How quickly can beams or frames be swapped if a forklift hits something?

-

-

Safety and inspection

-

Systems that include proper protectors, mesh and signage from day one will usually cost less to keep compliant long-term.

-

Choosing the right industrial storage solutions is as much about future headaches as it is about day-one price.

Step 7 – Bake in compliance and safety from the start

In Australia, compliant warehouse racking must be designed, installed and maintained in line with AS 4084.

When you choose your system and supplier, check that:

-

The design is certified to AS 4084 (latest version) for the specific configuration

-

Load calculations, frame types and beam sizes are documented

-

SWL signs and layout drawings are provided and installed

-

Impact-prone areas include proper protectors, barriers and guide rails

-

There’s a clear plan for periodic inspections and repairs

You can support this with:

-

Pallet Racking Safety in Australia: AS 4084 Explained in Plain English

-

How Often Should Your Pallet Racking Be Inspected?

-

Top 10 Racking Safety Mistakes We See On-Site (And How to Avoid Them)

-

Pallet Racking Inspection Checklist (Free PDF)

Build safety into your selection criteria – not as an afterthought once the racking is already in.

Step 8 – Questions to ask your racking supplier

When you’re down to a shortlist, the right questions will quickly separate a true warehouse storage systems specialist from a generic steel supplier.

Ask:

-

Who takes design responsibility?

-

Is there an in-house design manager/engineer who signs off drawings and calculations?

-

-

What standard is the design to?

-

Confirm AS 4084 compliance for the final layout and configuration.

-

-

What exactly is included?

-

Frames, beams, anchors, protectors, mesh decks, pallet supports, SWL signs, freight, installation and certification.

-

-

How will installation be handled?

-

Are installers experienced with heavy duty pallet racking and familiar with your industry (3PL, cold storage, trade supplies, etc.)?

-

-

What’s the plan for inspections and repairs?

-

Can they provide ongoing inspections, maintenance and a path to keep your industrial racking compliant over time?

-

Common mistakes when choosing pallet racking

A few pitfalls we see when people choose racking without a clear process:

-

Copying someone else’s layout

What worked in another site, another state or a previous job often doesn’t match your SKU profile, slab, or workflow. -

Designing around today only

No allowance for extra beams, extra bays or a future raised storage area – and you run out of capacity in 18–24 months. -

Ignoring pallets and packaging

Non-standard pallets and overhanging product that don’t match beam lengths or clearances can kill capacity and safety. -

Underestimating safety and compliance

Skipping protectors, SWL signs and inspections to save a few dollars up front usually leads to higher repair bills and risk later. -

Overcomplicating the system

Installing advanced high density storage systems or automation where simple selective or commercial pallet racking would do.

Bringing it all together

Choosing the right pallet racking for warehouses is about aligning five things:

-

Your stock and movement patterns

-

Your building and constraints

-

Your equipment and labour model

-

Your growth plan and budget

-

Your safety and compliance obligations

Get those clear, and the “which system?” question becomes much easier – and you can use focused guides like Pallet Racking 101 and Selective vs Double-Deep vs Drive-In vs VNA to fine-tune the mix rather than starting from scratch.

Need help choosing racking for your site?

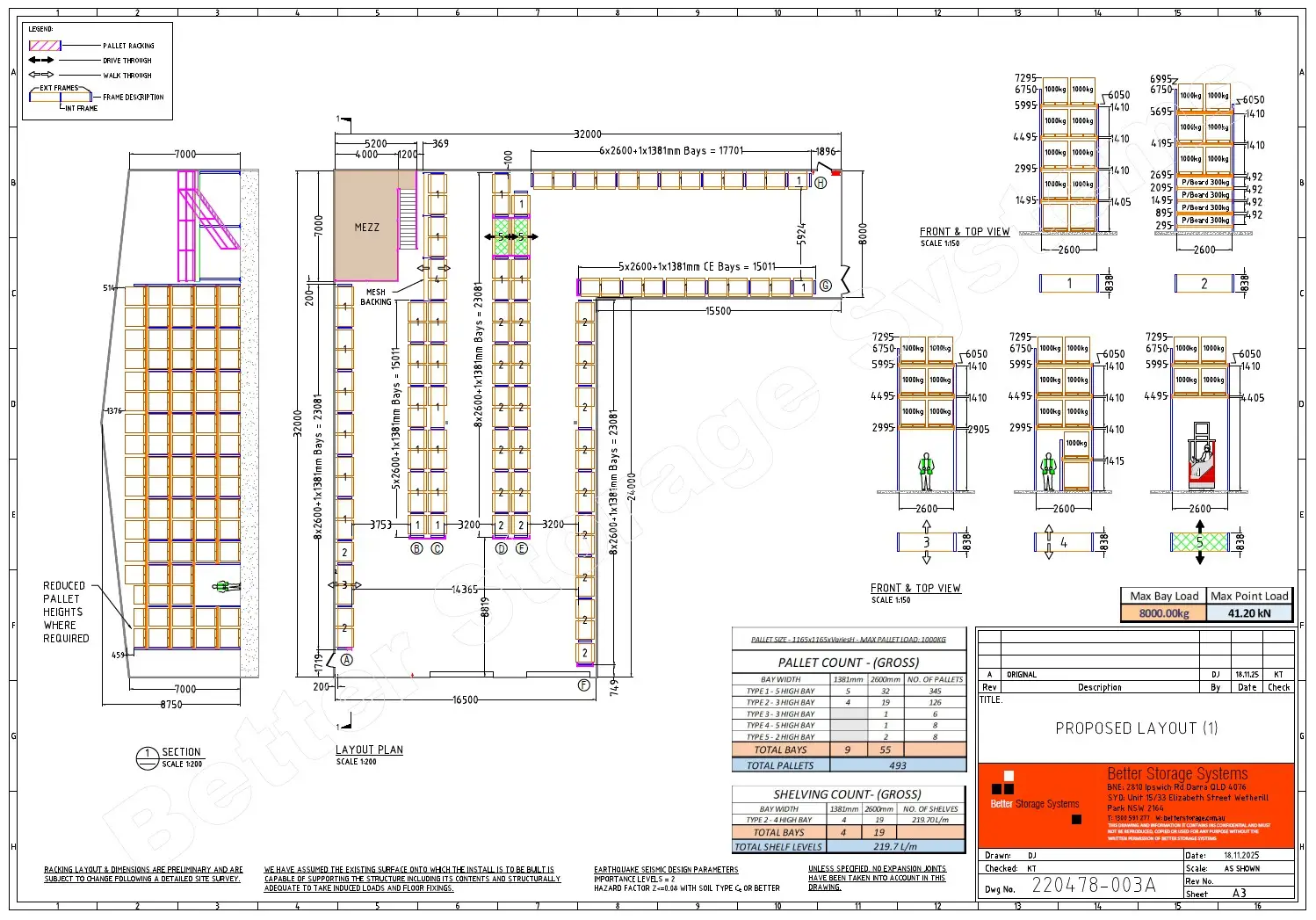

Better Storage Systems designs, supplies, installs and certifies industrial storage systems across Australia – from simple selective layouts to complex cold-store warehouse storage solutions with mobile and shuttle systems.

We can:

-

Analyse your SKUs, pallet types and throughput

-

Optimise your warehouse space optimisation and layout

-

Recommend the right mix of pallet racking systems, shelving and mezzanines

-

Provide a fully documented, compliant warehouse racking design to AS 4084

If you’d like to see what’s possible in your building, get in touch for a design and quote – and turn your warehouse into a safe, efficient, future-ready storage system.