Before you worry about which pallet racking system to buy, you need to know whether it will actually fit – safely – in your building.

This guide sticks to the geometry of warehouse racking:

-

How wide your aisles need to be

-

How much clearance to allow between pallets, uprights and beams

-

How to think about beam levels and usable height

We’re not rehashing racking types or buying decisions – those live in other guides. This one is about dimensions: the nuts-and-bolts of turning empty floor space into safe, efficient warehouse pallet racking.

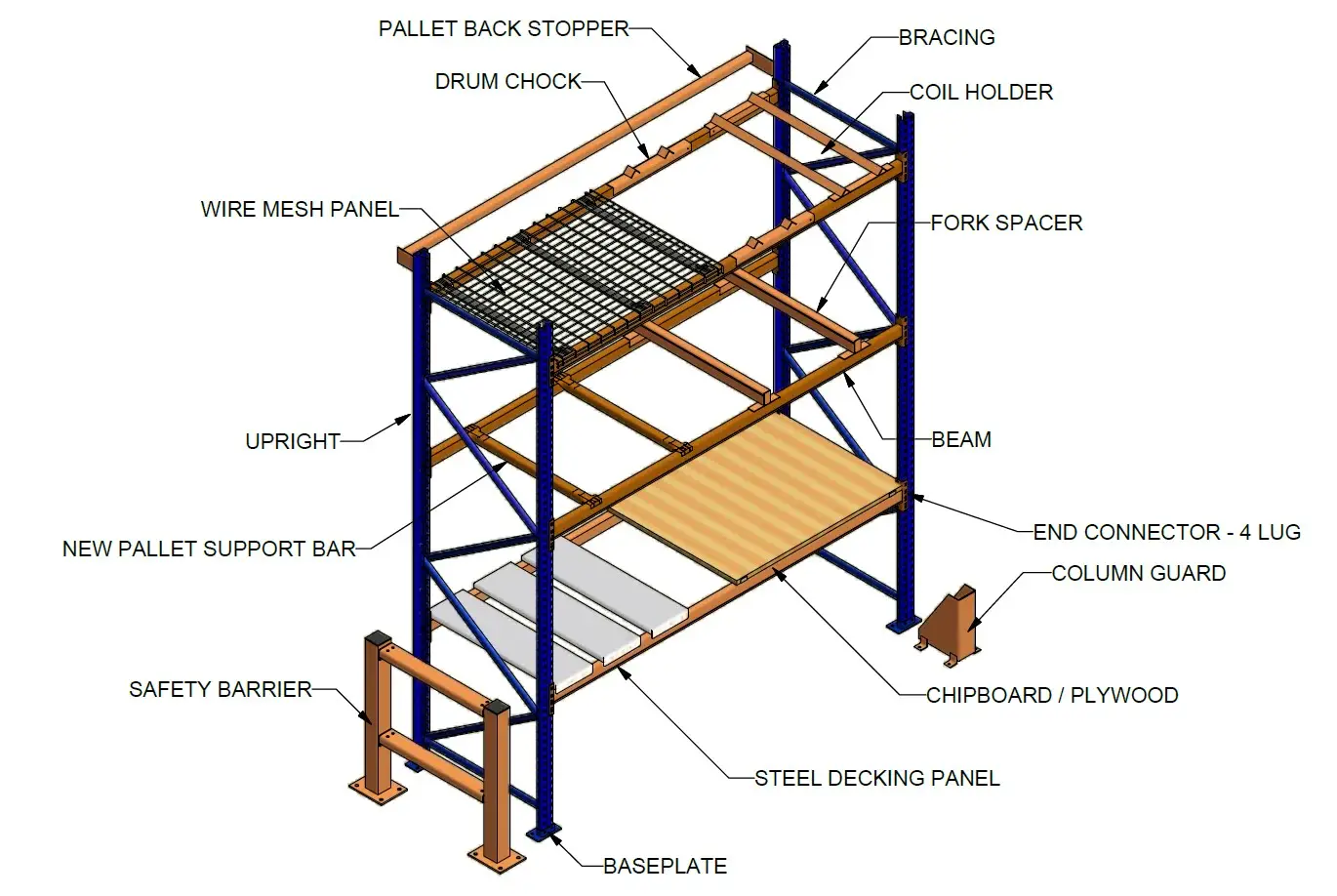

1. Key terms (in plain English)

You’ll see a few terms repeated in standards and manufacturer manuals. Here’s what they mean in practice:

-

Aisle width

The clear distance at floor level between racking runs or between racks and walls/obstructions. EN 15620 defines it as the minimum dimension across the aisle at floor and beam levels between unit loads or structure. -

Racking aisle width

Specifically the distance between rack structures (steel to steel), not including product overhang. -

Clearance

The “spare space” between pallets and steel – side-to-side, above and behind – that lets operators place and remove loads without constant contact. -

Beam level

The height of a pair of load beams above the floor. The spacing between levels is often called beam pitch. -

Clear opening dimension (COD)

The vertical clearance between the top of the pallet and the underside of the beam above. Some internal standards call this out explicitly – e.g. 75–100 mm minimum depending on height.

These basics drive everything else in your warehouse layout design.

2. Aisle width basics: what really sets the number?

There’s no single “right” aisle width for warehouse racking. The number is driven by:

-

Forklift type and turning radius

Counterbalance, reach, VNA, walkie stacker – each has different turning and operating envelopes. -

Pallet size and overhang

CHEP/Loscam 1165 × 1165 pallets sitting on 1100 mm-deep frames will overhang into the aisle, which must be allowed for. -

How you operate

-

One-way vs two-way traffic in aisles

-

Need for pedestrians in the same aisle

-

Speed and intensity of traffic (slow store vs fast DC)

-

Industry design manuals often start with simple clearance rules, for example:

-

Minimum 100 mm between truck and pallet face

-

Minimum 300 mm between two trucks passing in the same aisle

-

Extra clearance (e.g. 175 mm+) in fast-moving environments

Those clearances sit on top of the forklift manufacturer’s minimum turning curve, so you should always confirm the final aisle width with your MHE supplier.

Typical working ranges (ballpark only)

Actual numbers must come from your forklift specs and design calculation, but as rough guidance:

-

Wide aisle – counterbalance trucks: often in the 3.5–4.0 m range

-

Wide/narrow aisle – reach trucks (Class 400): often around 2.7–3.0 m, depending on pallet size and height

-

Very narrow aisle (VNA – Class 300): aisles are typically 1.6–1.9 m, but trucks run on rails or wire guidance and floors must meet tight flatness tolerances.

These ranges show why you can’t copy a layout designed for counterbalance and expect it to work for VNA, or vice versa.

Don’t forget cross-aisles and intersections

Down-aisle width gets all the attention, but cross-aisles, intersections and end-of-run areas can be your real bottlenecks:

-

Cross-aisles need additional clearance to allow turning, queuing and (often) temporary pallet staging.

-

Design manuals recommend minimum clearances of a few hundred millimetres between trucks and obstacles, plus extra space if you want pedestrians in the same area.

If you’re working on warehouse space optimisation, remember that making aisles too tight can actually reduce throughput and increase rack damage.

3. Pallet clearances inside the bay

Once you’ve picked a frame depth and beam length, you still need to give each pallet “breathing room” inside the bay.

Most industrial pallet racking manuals and standards follow similar logic.

Side-to-side clearances

A common design rule set (reflected in Australian manuals) is:

-

Minimum 75 mm between the pallet and each upright

-

Minimum 100 mm between pallets (pallet-to-pallet) on the beam

That’s the bare minimum to satisfy standards and allow reasonable operation; many sites add more where operators are less experienced or pallets are inconsistent.

Depth clearances and overhang

On the depth (front-to-back) of the bay:

-

Typical design allows frame depth slightly less than pallet depth, so the pallet overhangs front and back.

-

Guide values:

-

For a CHEP pallet (1165 x 1165mm), a frame depth of 838 mm is common.

-

Manuals often allow ~25 mm total rear clearance between pallets or between pallet and upright.

-

You also need to consider:

-

Bulging or “fanning” of cartons on the pallet

-

Stretch-wrap tails

-

Slight variations in pallet size and condition

Getting these small numbers wrong can cause constant “hang-ups”, pallets catching on uprights, and increased rack impact.

4. Vertical clearances and beam levels

This is where beam levels and beam pitch come in.

You’re trying to stack as many safe levels as possible into your clear height without making the system hard or dangerous to operate.

Vertical clearance basics

The key allowances are:

-

Pallet load height (HL) – from the floor/beam to the very top of the load

-

Beam height – the physical depth of the load beam (often around 90–120 mm)

-

Vertical clearance (COD) – the gap between the top of the load and the underside of the next beam

Design documents give typical minimums such as:

-

≥ 75 mm vertical clearance for lower installations

-

≥ 100 mm vertical clearance for higher racks or where visibility aids are absent

-

EU guidance increasing clearances again above 9 m and 13 m to reflect harder positioning at height.

Australian manuals also call out 100 mm as a recommended minimum between the top of the pallet and the underside of the next beam, especially where operators are less experienced.

A simple worked example

Let’s keep it practical. Say you have:

-

CHEP pallets, 1200 mm total loaded height

-

Beam sections approx. 100 mm high

-

Target 100 mm vertical clearance (COD) above each pallet

-

Clear height under services/sprinklers: 8 500 mm

For each level (excluding ground):

Beam pitch ≈ pallet height + clearance + beam height

1200 + 100 + 100 = 1400 mm

If you aim for three beam levels above floor:

-

3 × 1400 mm = 4200 mm from top of floor pallet to underside of highest beam

-

Add approx. 1200 mm (top pallet at top level) + 100 mm clearance to sprinklers/services = ~5500–5600 mm used

You’re comfortably inside 8.5 m, so you might even be able to add a fourth level depending on slab loading, truck lift height and design calculations.

The exact numbers must be checked and certified by your racking supplier/engineer, but this shows how beam levels are built from pallet height, beam size and clearance.

Don’t forget deflection

Beams bend slightly under load. Design manuals use deflection limits like L/180 of the span (where L is clear beam length) to ensure beams don’t sag excessively.

If you try to squeeze clearances too tight, normal deflection plus small erection tolerances can wipe out your safety margin.

5. Pulling it together: turn empty space into a basic layout

Here’s a simple way to think about a first-cut warehouse storage system layout, without duplicating the full planning process from other guides.

-

Start with the building envelope

-

Clear height under sprinklers and services

-

Column grid and any hard obstructions

-

-

Choose a sensible top-of-rack height

-

Usually 300–500 mm below the lowest obstruction to allow for deflection, services and safe operation.

-

-

Set your beam pitch from pallet height and clearance

-

Use known pallet heights and a clearance rule (e.g. 100 mm).

-

Work up from the floor to see how many levels fit below your chosen top-of-rack.

-

-

Check against your forklift capability

-

Maximum lift height (with a safety margin)

-

Recommended working aisle for your pallet dimensions

-

-

Lay out aisles and cross-aisles

-

Use forklift turning data plus clearances (100–300 mm+) as discussed above.

-

This gets you a rough but realistic layout you can hand to a racking designer to be engineered, certified and optimised.

6. Common layout mistakes (purely dimensional)

Some of the most expensive layout problems come from small dimensional decisions:

-

Aisles based on “what we had before”

Reusing an old layout without checking against current forklifts and pallets often produces aisles that are too tight or too wide for today’s gear. -

Ignoring pallet overhang

Designing frame depth equal to pallet depth leaves no room for overhang or bulging – pallets then “fight” with uprights and safety clearances vanish. -

Inconsistent beam levels across the shed

Different pitches in different areas make slotting, labelling and capacity calculations much harder. -

Not allowing for future re-slotting

Beam levels that work for today’s products may be a poor fit for tomorrow’s taller or shorter lines. Small changes in vertical clearance now can unlock a lot of flexibility later. -

Running aisles too close to columns, walls or guards

Forklift turning curves need clear “run off” around obstructions; if you don’t leave it, you’ll get chronic impact damage.

7. Where the standards and manuals fit in

For compliant warehouse racking, racking designers draw on a combination of:

-

Australian Standard AS 4084 for steel storage racking

-

European standards like EN 15620 for tolerances and clearances

-

Manufacturer design manuals, which:

-

Define minimum clearances (75–100 mm side/vertical, 25 mm depth, etc.)

-

Specify beam deflection limits and height classes

-

Translate higher-level standards into practical dimensions

-

You don’t need to memorise the standards, but it helps to understand how your warehouse layout design will be checked and signed off.