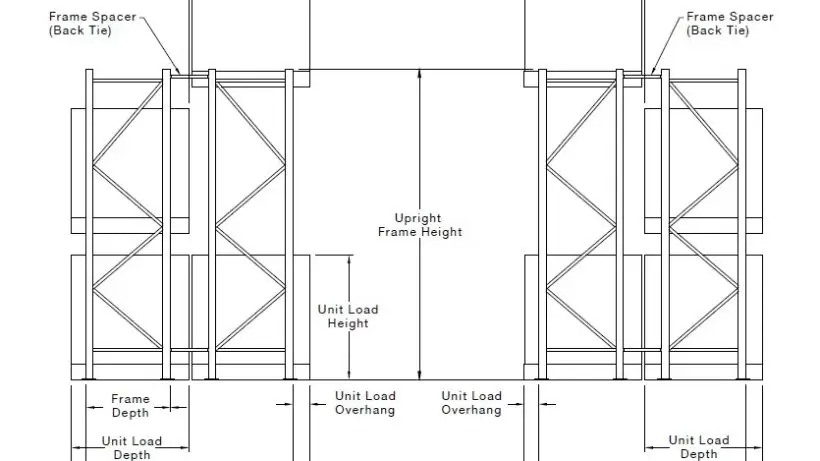

Frame Depth vs Pallet Overhang: What Actually Matters for Safety and Handling

Why “Frame Depth vs Pallet Overhang” Isn’t Just a Design Detail On a drawing, frame depth and pallet overhang look like a couple of small numbers in the middle of a big layout. In a live warehouse, they decide whether: Pallets sit stably on beams or rock and sag Forklift